High-Safety, Multi-channel AFE Products in Grid-Side Energy Storage

The widespread economic and social transformation known as the "dual carbon" strategy presents formidable challenges and significant opportunities for the energy industry. By 2021, China's non-fossil fuel-based electricity generation capacity exceeded that of coal, reaching 1.12 billion kilowatts, with hydro, wind, and solar capacities surpassing 300 million kilowatts. As renewable energy generation continues to expand, there is mounting pressure on power systems to integrate these intermittent sources effectively. Energy storage technology is recognized as pivotal in supporting the large-scale deployment of new energy solutions, heralding what is seen as the third industrial revolution.

Beyond China, nations, including the United States, the European Union, and Japan, have released comprehensive energy storage technology roadmaps between 2017 and 2018. These plans highlight lithium-ion batteries as a key focus area and underscore substantial investments in research and development.

With a surge in energy storage demand on the consumer side, grid-side energy storage is poised to become a pivotal market segment. Given the volatility inherent in renewable energy sources, achieving stable and seamless grid integration requires the rapid adoption of integrated "generation-grid-load-storage" models.

Self-built energy storage systems frequently utilize lithium-ion battery solutions in new energy power plants. This choice is particularly evident following the widespread adoption of lithium iron phosphate batteries in electrochemical storage applications. These batteries offer numerous advantages, including millisecond-level response times, flexibility, and high charge-discharge frequencies. The "new energy + energy storage" configuration has become a standard requirement in benchmarking new energy initiatives. Propelled by government incentives and burgeoning market demands, it is anticipated to create a market worth hundreds of billions by 2025.

In summary, energy storage is a crucial choice for the future development of the power industry, especially within the expansive market outlook of grid-side energy storage. Energy storage products are advancing towards higher capacities, diverse application scenarios, and recyclable development, yet they face pressing technological challenges.

(1) Safety: As installation capacities scale from megawatts to gigawatts, the stability of systems, battery cycle life, and overall lifecycle impacts on project returns become increasingly critical. System safety and stability are foundational, with Battery Management Systems (BMS) as indispensable core components in energy storage systems.

(2) Cost-effective: High energy efficiency in energy storage systems is essential for optimizing the cost-performance ratio. Beyond improving the efficiency of the individual cells, enhancing the overall system performance also plays a significant role. Within this framework, the cost-performance ratio of the Battery Management System (BMS) is a key consideration.

(3) Operational Control Strategies: Energy storage operational strategies encompass many considerations, including mechanical structures, electronic systems, big data, communications, and computing. Irrespective of the strategy chosen, the operational control strategy of communication systems is a central element ensuring timely and precise execution, with BMS communication functions playing a pivotal role.

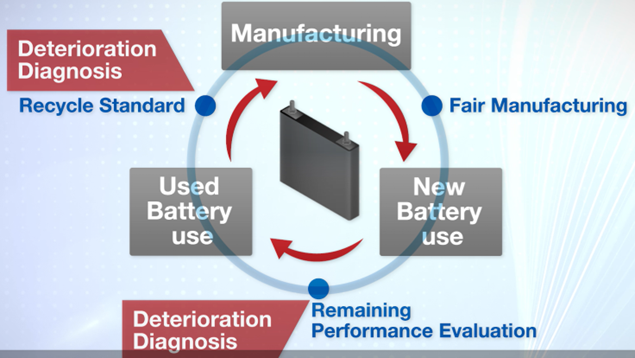

(4) Closed-loop Industry Chain: The energy storage industry chain has yet to establish a complete closed loop, and there remains a need to perfect the recycling of energy storage facilities. To address this gap, Nuvoton Technology plans to introduce AFE products integrated with advanced battery deterioration diagnosis technology by 2025.

Given these considerations, Nuvoton Technology recommends adopting higher-specification automotive-grade AFE products in the design of grid-side energy storage systems, particularly their high-safety and high-series AFE products. Nuvoton Technology has consistently aimed to deliver unique value across the battery industry value chain, exemplified by industry-leading 25-channel AFE products and the upcoming Battery Deterioration Diagnosis technology, continuing to provide high-quality solutions.

【Safety】

Nuvoton emphasizes a dual focus on "intrinsic safety" and "functional safety," asserting that their effective integration is crucial for achieving genuine safety.

Regarding "functional safety," Nuvoton has introduced AFE products for automotive applications that meet the rigorous ASIL-D standard, which is the highest in the automotive functional safety hierarchy. Leveraging over a decade of experience across major global automotive manufacturers, Nuvoton's products facilitate the attainment of SIL 4, the highest industrial safety level, for energy storage BMS systems.

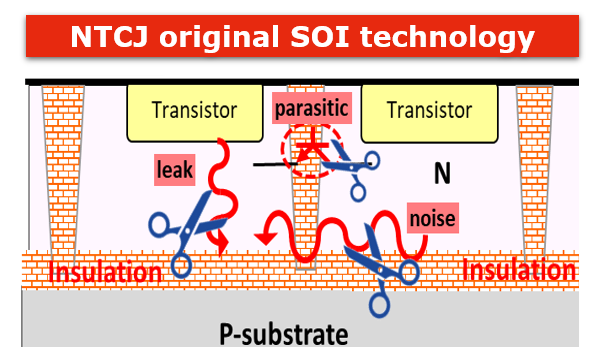

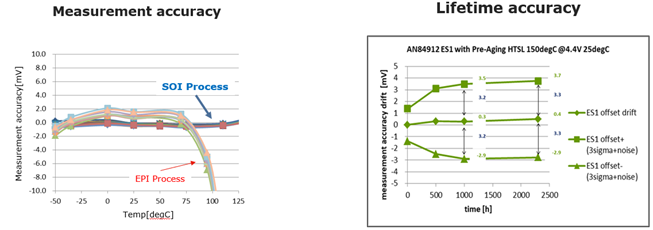

"Intrinsic safety," on the other hand, pertains to the robustness of the chip itself. Nuvoton employs the mature SOI (Silicon On Insulation) process in its BMS AFE products to achieve this goal, with millions of units already in production. Unlike traditional EPI processes, SOI technology requires higher process voltages and specific techniques but offers superior characteristics, including increased voltage surge tolerance. As Figure 3-1 below illustrates, the SOI process diagram demonstrates how DTI (Deep Trench Isolation) technology isolates functional modules within the chip, enhancing performance regarding parasitic elements, noise, and leakage currents.

Figure 3-1

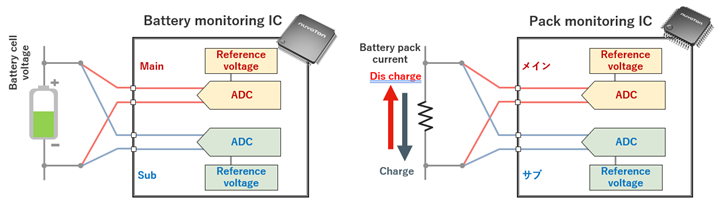

Furthermore, Nuvoton's various battery management products, including AFE products for automotive applications, adopt a fully redundant design to prevent common-mode failures. This fully mirrored design facilitates customer battery safety strategy design and inspires engineers to develop innovative designs derived from dual mirrored acquisition systems. Nuvoton believes that "SOI technology + full redundancy" is crucial for achieving "safe redundancy."

Figure 3-2

Thirdly, Nuvoton’s automotive AFE products provide high-precision measurements ranging from ±2.5mV to ±1.5mV, ensuring accuracy throughout their lifecycle, including post-aging precision. This capability effectively monitors the status of batteries and cells, laying a solid foundation for stable and reliable battery operation.

Lastly, communication security is equally critical for Nuvoton. Apart from supporting a broader range of communication security layer designs, bidirectional daisy-chain configurations, and faster, more diverse communication rate settings, Nuvoton's AFE products also support other communication bus options, such as direct SPI connections to meet the industry's needs for non-daisy-chain BMS systems.

【Cost-effective】

Any product's commercialization must consider evaluating its cost-performance ratio. For energy storage products on the grid and related BMS systems, we believe such evaluations must be conducted under the premise of high safety and stability.

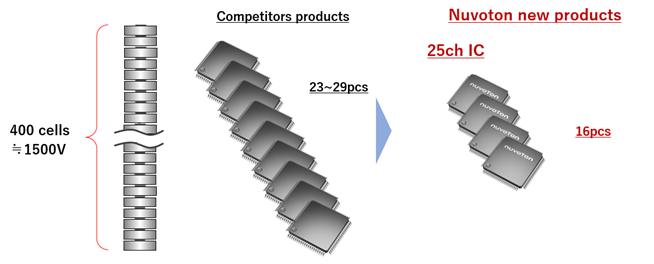

For example, as shown in the diagram below, using AFEs with multi-channel in the composition of grid energy storage BMS systems can significantly reduce BOM costs.

In today's market for grid energy storage, configurations are popularly found in ranges such as 40 to 60 series and even up to 100 to 110 series for energy storage battery packs. 20-series and 25-series AFE products are ideal choices for optimal solutions. For example:

For 40-60 series battery packs: 2KA84950UA (2 * 25S) + 1KA84930UA (1 * 20S)

For 100-110 series battery packs: 2KA84950UA (2 * 25S) + 3KA84930UA (3 * 20S)

Nuvoton achieves this flexibility through pin-compatible designs (applicable within the same generation of AFE products). The related data acquisition channels also support the direct Bus-bar connection and include negative pressure monitoring. Furthermore, AFE products incorporate modular internal modules, facilitating ease of reuse and portability.

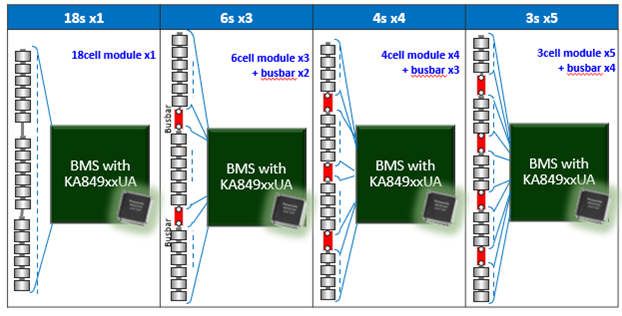

Additionally, higher series configurations facilitate customers in expanding their selection of cell modules, ensuring a robust supply while enabling flexible choices of the most cost-effective cell modules available in the market for battery assembly. This capability effectively manages existing inventory to optimize product and management cost-effectiveness. Taking the 20-series AFE KA84933UA as an example, the diagram below clearly illustrates the advantages of the 20-series AFE over the 18-series AFE products.

From the perspective of energy storage batteries themselves, optimizing the utilization, cycle life, and energy efficiency of battery cells can indirectly improve the cost-effectiveness of energy storage system operations. This requires BMS systems to conduct thorough SOC calculations and precise SOH estimations. Consequently, AFE products must provide high-precision data acquisition and strive for consistent V-I synchronous measurements whenever feasible.

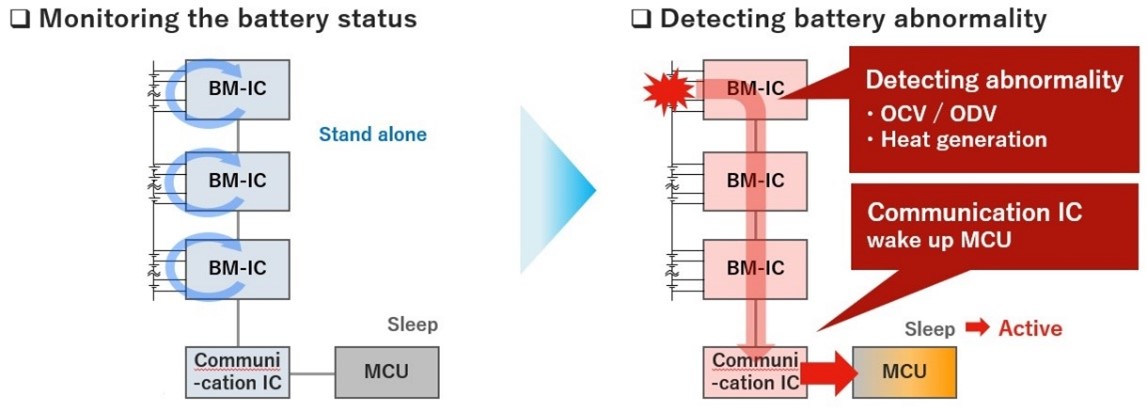

Nuvoton's automotive-grade AFE products achieve V-I synchronous functionality within the 10us range, currently setting the fastest record in the industry. Additionally, these AFE products include a built-in wake-up feature that enables accurate measurements and abnormality detection even during MCU low-power sleep mode, thereby balancing energy consumption and safety.

【Closed-loop Industry Chain】

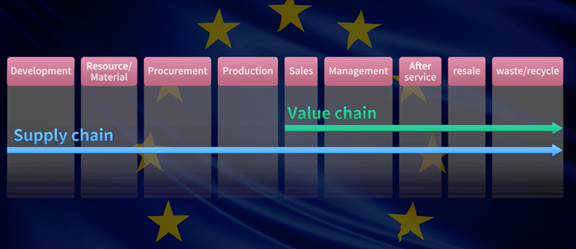

Nuvoton is committed to being a value provider across the entire battery industry chain. In addition to enhancing traditional battery safety, we focus on constructing mechanisms for the value cycle utilization of batteries from the supply chain and value chain perspectives. The phased utilization and recycling of batteries have always been among our planned technical strategies. With Europe introducing concepts such as carbon footprint and battery passport and progressively implementing them, Nuvoton intends to maintain a leading position in this field.

By 2025, Nuvoton plans to launch AFE products equipped with built-in Battery Deterioration Diagnosis technology to support customers in responding to market changes and completing the closed loop of the industry chain. The 10us V-I synchronous measurement mechanism provided by Nuvoton's automotive-grade AFE products enables customers to rapidly and accurately assess cell internal resistance and battery health, laying the foundation for supporting related functionalities.

In conclusion, KA849xx series automotive-grade AFE products, leveraging high-voltage SOI technology, full redundancy, high-precision acquisition throughout the lifecycle, high series connection capability, and reverse wake-up design, along with its future product development path, aim to meet current demands of grid-side energy storage BMS systems and align with future technological trends. We look forward to collaborating with more customers to develop products that better comply with "dual carbon" policy planning.

Nuvoton has developed a comprehensive product and technical development path in the BMS AFE product field. For more product information, please follow our official website (www.nuvoton.com) or contact us directly.