Multi-channel AFE Technology in New Energy Vehicles

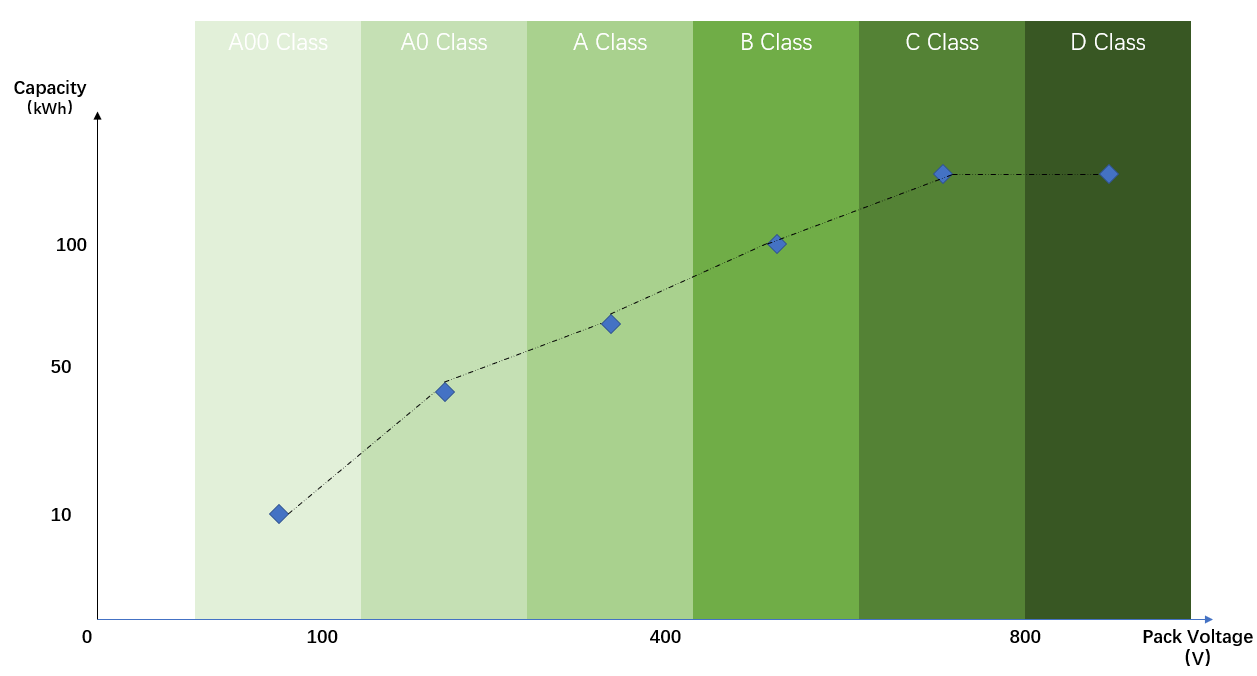

The battery industry for new energy vehicles is rapidly evolving in multiple dimensions and directions. Each battery management system (BMS) follows its distinct development path, with market choices indicating clear trends. Given the diverse needs of different vehicle grades, a comprehensive analysis based on Figure 1-1 provides a starting point.

Figure 1-1

Driven by global low-carbon policies and increasing consumer demands, the market is transitioning from A00/A0 to A/B grade vehicles. As depicted in Figure 1, battery capacity, pack voltage, and cell series numbers are rising towards 100S, 200S, and beyond. This trend poses significant challenges for battery design and BMS AFE products, requiring solutions for higher voltage endurance, insulation safety, and effective battery state-of-charge (SOC) and state-of-health (SOH) management. BMS providers, battery manufacturers, and automotive OEMs face ongoing management challenges with current and future products.

In response, Nuvoton Technology develops automotive-grade AFE products with advanced technological capabilities. These products ensure high safety, extended durability, and seamless integration into new energy vehicle power systems. Safety, endurance, and compatibility have always been the core design principles of Nuvoton's BMS AFE products, ensuring decades of reliable customer service.

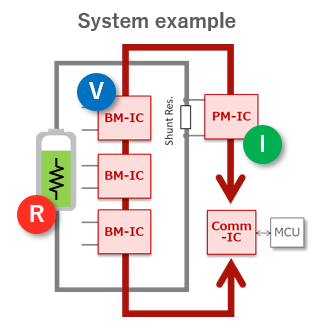

Figure 2-1

[Safety]

Nuvoton Technology emphasizes both "intrinsic safety" and "functional safety," believing that their effective combination ensures genuine safety. "Intrinsic safety" refers to the inherent robustness of the chip itself. Nuvoton's automotive-grade AFE products achieve the industry's highest functional safety standard ASIL D and successfully employ Silicon On Insulation (SOI) technology in BMS AFE products to enhance intrinsic safety. Over ten million units are currently in mass production and deployment.

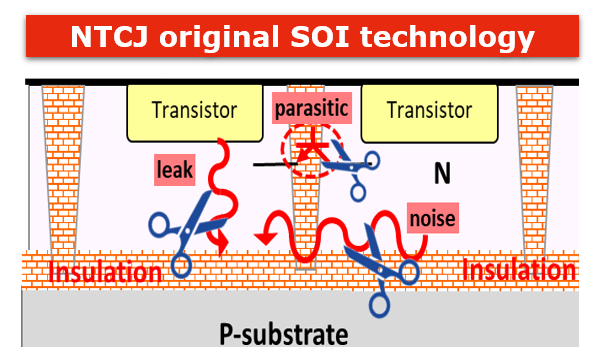

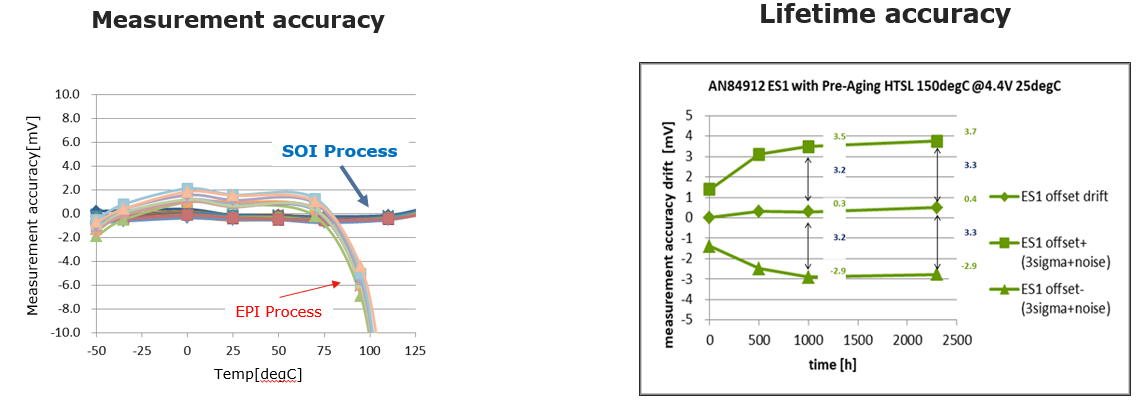

Unlike traditional EPI processes, SOI processes require higher voltages and specialized technical support. However, these requirements yield superior product characteristics. In the SOI process illustrated in Figure 3-1, internal chip modules are isolated into independent insulation regions using Deep Trench Isolation (DTI), significantly improving performance by addressing parasitic components, noise, and leakage current issues.

Figure 3-1

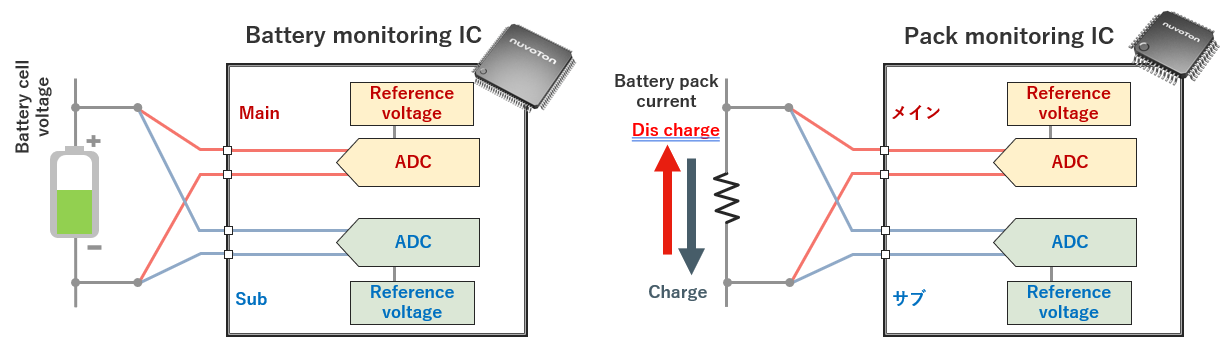

On the other hand, Nuvoton Technology's various series of battery management products, including automotive-grade AFE products, adopt a complete redundant design to mitigate common-mode failures effectively. The full mirror design facilitates customer design and the formulation of battery safety strategies and allows engineers to leverage innovative designs using dual sets of mirrored acquisition systems, thereby providing new value propositions. Nuvoton Technology believes that "SOI technology + full redundancy" is essential for achieving true "safe redundancy."

Figure 3-2

Furthermore, Nuvoton Technology places significant emphasis on communication security. Features such as broader communication security layer design, support for bidirectional daisy chains, and faster and diverse communication rate settings effectively balance communication security and speed.

[Extended Endurance]

Deep SOC estimation demands AFEs to provide high acquisition precision and consistent V-I synchronous measurements. Nuvoton Technology believes that true "precision" should guarantee accuracy at present high standards and throughout the battery's lifecycle. Otherwise, issues like battery lifespan and deep SOC accuracy cannot be assured, leading to concerns such as "range anxiety" and impacting user experience. Nuvoton Technology's adoption of SOI technology differs from the industry's widely used conventional EPI processes.

Figure 3-3

Figure 3-3 clearly shows that Nuvoton automotive-grade AFE products provide comprehensive accuracy, backed by specific and effective assurances in technical specifications.

[Platform Compatibility]

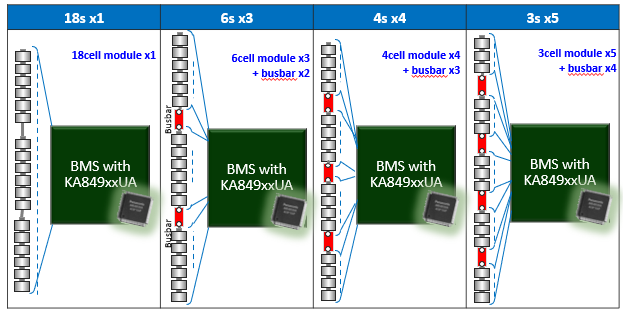

Nuvoton leads the industry with its AFE products (up to 25 cells), ensuring robust compatibility. For instance, the KA84933UA AFE from Nuvoton supports optimizing battery module compatibility, meeting the needs of various 18-cell battery configurations. Its design characteristics cater to the platform requirements of BMS providers, optimizing battery inventory management for manufacturers and facilitating diverse supply strategies for vehicle manufacturers.

Figure 3-4

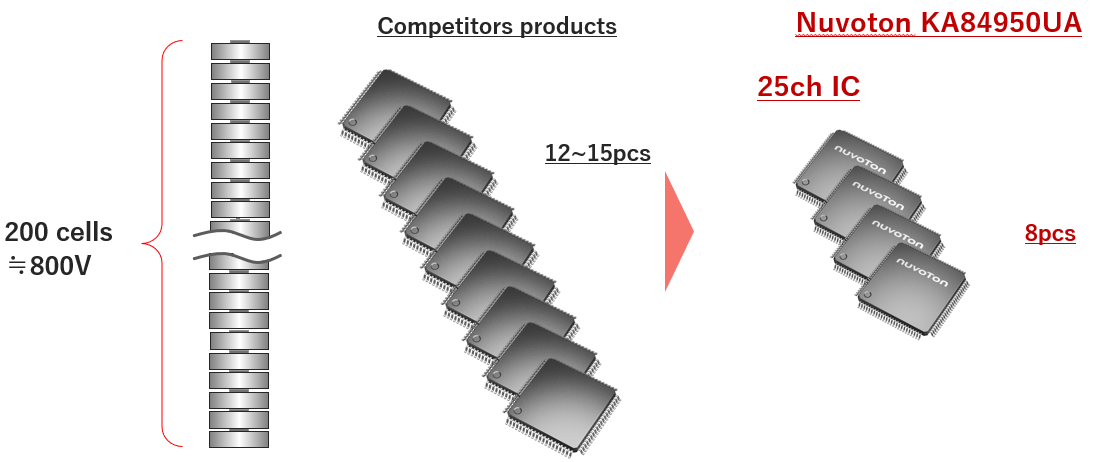

At the same time, the cost advantages of high-cell designs are evident. Take the KA84950UA AFE with 25 cells as an example:

Figure 3-5

With fewer AFE units, the system's security risk nodes decrease, improving system polling rates and enhancing system security.

In summary, Nuvoton Technology introduces the KA849xx series of automotive-grade AFE products, leveraging high-voltage SOI technology, full redundancy, high-precision acquisition throughout the lifecycle, and high-cell count designs. These products are tailored to the evolving needs of new energy vehicle batteries, offering an efficient design approach amidst the prevailing trend of hardware standardization and fostering innovative design applications.

Nuvoton Technology has dedicated itself to developing BMS AFE products and shaping a comprehensive product and technology roadmap. For more details, please visit Nuvoton Technology's website and contact us.